Taking back control in a turbulent market.

Medfreight faces many challenges in its industry. Over-capacity international crises have crushed the prices, reducing profits across the industry. At the same time, the exchange rates for USD, EUR and RON (the local currency) were jumping like crazy from one day to another, while moving from a firm offer to the receipt of payment took up up to 3-4 months.

There wasn’t much they could do about those challenges. But while Medfreight couldn’t change the world, they could change themselves.

The business demand: Get back in control

The proposed solution: Digital transformation

Identifying pains of each stakeholder

Establishing key business objectives for the digital transformation involved a deep understanding of the industry and the challenges it faced. We brought our technological know-how to the table while Medfreight’s management brought its business know-how. This allowed us to define the objectives together.

What management asked for:

Cost control: A daily update of costs and income based on currency fluctuations.

Current status: For each order.

Location of each resource: I.e. conveyance, containers, etc., grouped based on several factors including orders, customers, status and ID.

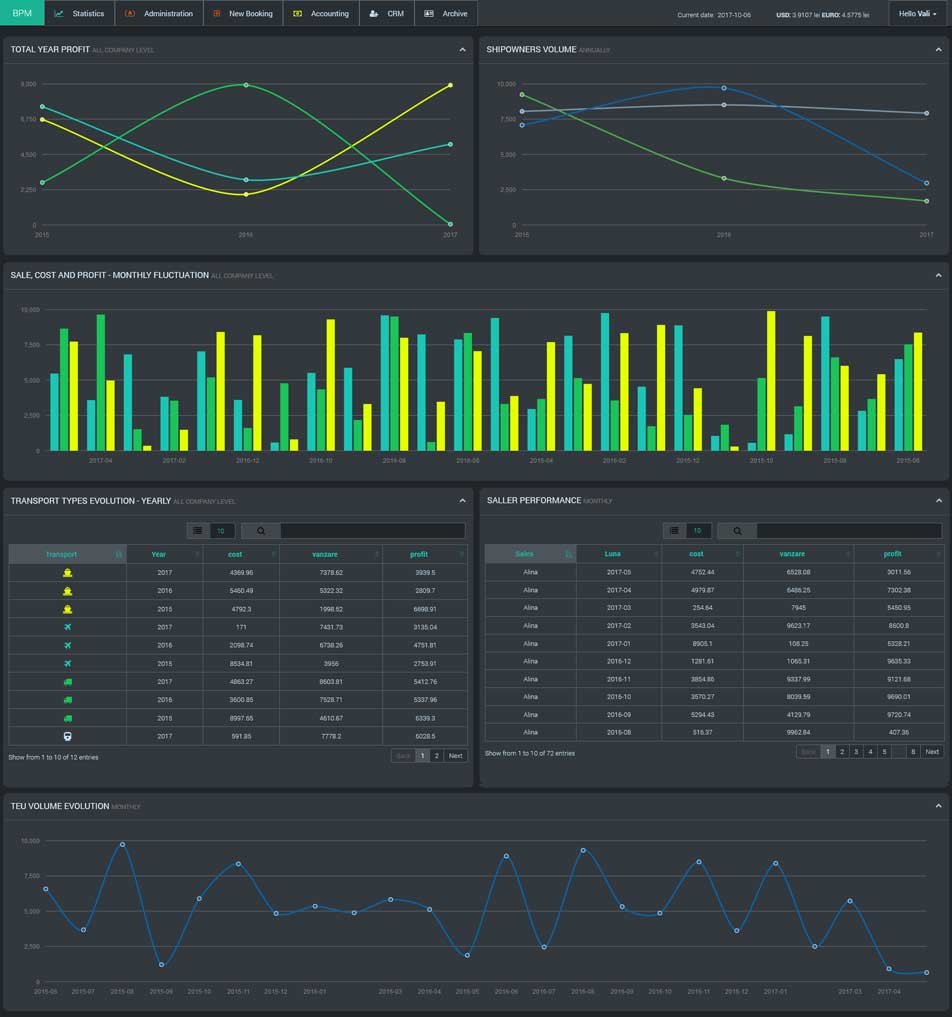

Statistics: With freight cost evolution for each port they operate and each ship owner they work with.

Centralized information: Including documentation for each order.

CRM: With customers’ addresses, contact details and contracts, as well as their overall revenue and profit.

To get a 360° perspective, we interviewed the management and future users, asking questions about what worked and what didn’t, which processes they wanted to change and what operational challenges they faced.

What employees asked for:

The adoption rate is one of the main challenges in a digital transformation project. That’s why asking employees for their opinion was so important.

Things needed to change: There was a general consensus that the current system needed to be modernized. Employees also acknowledged the objectives agreed with management and filed a long list of requested features.

While staying the same: There was also the classic fear of change. “What will the new system allow and not allow me to do? What if I need to do a specific task as an exception and the new system prohibits it?” These were all legitimate questions and they needed to be addressed.

The biggest risk to success is not embracing digital transformation. The biggest risk to success is not embracing the fact that the world is changing and that the way you do business, the way you operate, the way you interact with customers, the way you innovate, all of that is going to be different.

Satya Nadella, CEO, Microsoft

The solution

Step One: Get rid of the (need for) paperwork.

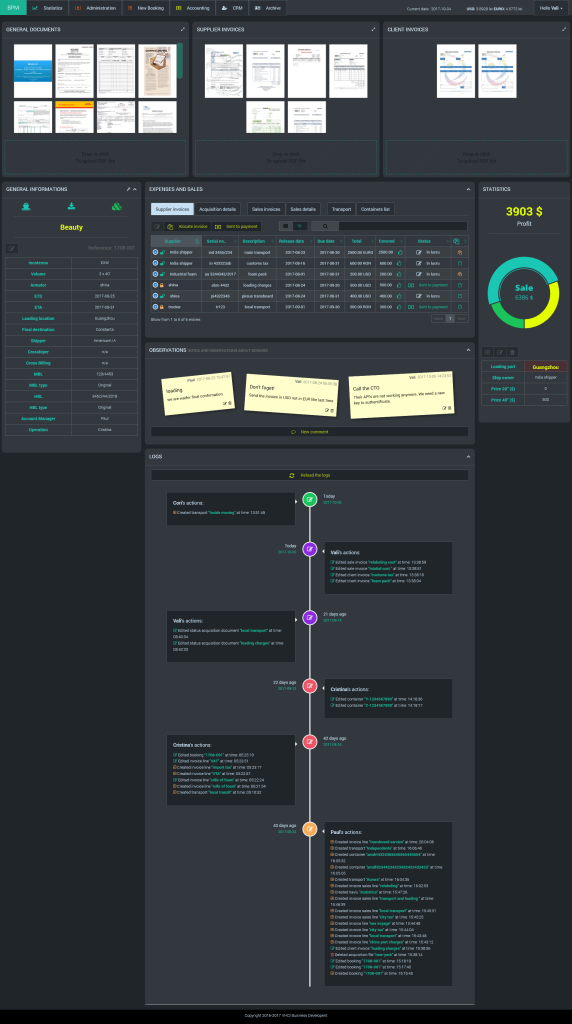

For every type of document (i.e. non-fiscal, supplier invoices and sales documents), we designed a drag and drop upload section. Once a file was dropped (uploaded) and its integrity confirmed, specific details were requested such as tags to be used for search and filtering. To make it easier to visually recognize the documents, an image thumbnail was created and displayed instead of a text link.

The (super) shortened version of the workflow

Financial documents were associated with an order and had a life-cycle with several steps and ownership passing from one role to another according to the business’s workflow.

Goods (referred as containers) were associated with a registered conveyance.

Files and data were added and updated by different roles according to internal processes. An immutable log recorded every data-changing action performed by every user and transparently displayed them upon request.

Step Two: Connect everything.

An order act was created as a non-exclusive collection of documents, containers and conveyances using meta-information such as current status, daily updated financial margins and special information. Some elements, like ships or invoices, could span across multiple orders and so an integration mechanism with fail-safe scripts for deleting and/or modifying was implemented.

Orders were correlated with customers and suppliers to determine revenue, profit, volume and other specific data used in statistics.

Step Three: Make the users love the new system.

Once the digitization process was complete, it was time to take advantage of it:

- Clear statuses for each order.

- Automated reports exported directly in PDF or Excel format.

- Easy ship management.

- Automated ship delay notifications for customers.

- Daily currency updates showing their impact on each order.

- Customer and supplier performance analytics.

- Plus a ton of other features!

How digital transformation made life easier for every job in the company

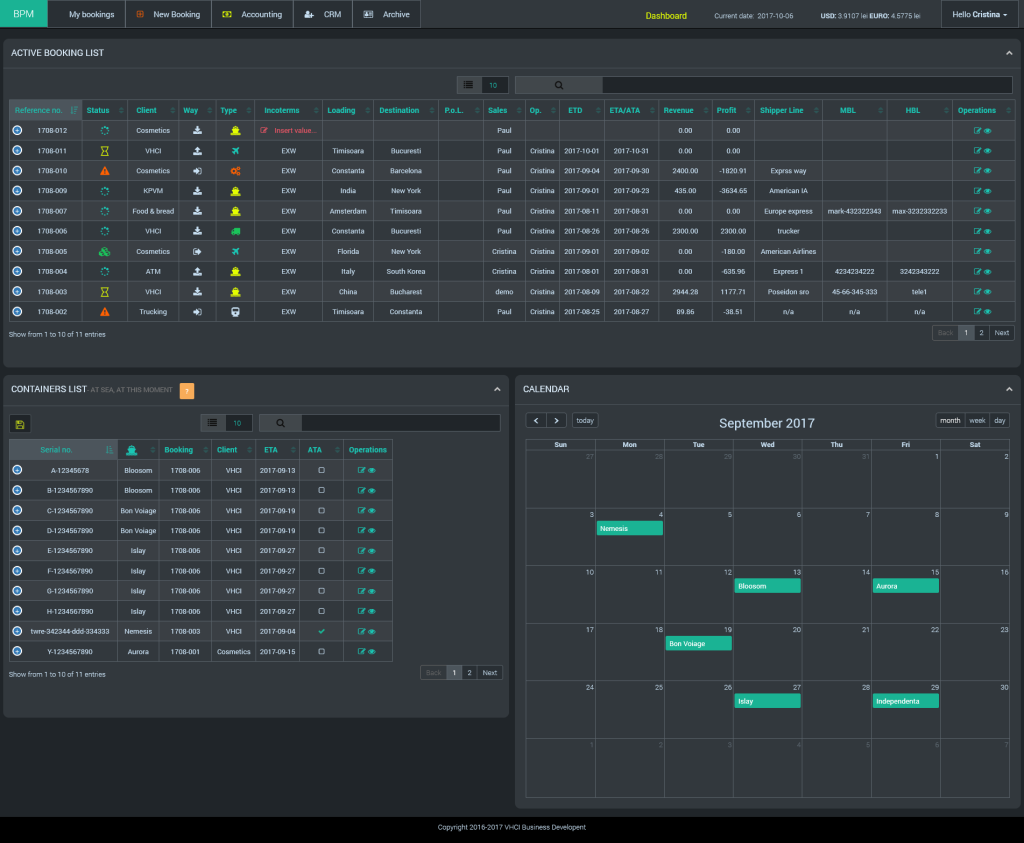

Ship management: If a ship was running late or if it arrived sooner than expected, users could just drag it to a new arrival day in the calendar, and it would automatically notify customers. If the ETA was still unknown, users could leave it unfilled, and the entry would appear in a specially designed area, awaiting placement on the calendar.

Container management: Users could enter the ship name, voyage, customer name, booking order, or any other keyword. The system would then generate a list, ready to be exported as a PDF, XLS, or CSV — or sent directly to the printer.

Time management: The personal calendar was designed to show all events – like ship arrival – in a single interface.

Document management: Documents could be spotted with ease by looking at the thumbnails or searched for using any keyword within the table. Users could see it as a PDF or download it to their computer.

Improved cooperation: When users needed a decision from management about a particular situation, they could mark it as “needs review,” and a big red warning sign would remain until management provided a resolution.

Financial health: A red flag is displayed if profit turns negative due to currency fluctuations.

Price management: Users could check overall revenue and profit to decide if a deal was worth it — which was useful when a customer tried to negotiate lower prices.

Simplified accounting: The accounts team could view accounts payable and receivable using a donut chart for easier visualization. If invoices were incorrect, they could be flagged and disputed, and when invoices were paid or money was received, they could easily be marked as complete within the drag-and-drop interface.

Order management: The current status of each order was visible on the general dashboard page. If support was needed, it would be flagged from within the display.

Sales management: Revenue, profit, and cash-flow status were all clearly visible and updated daily with the currency’s current value. Users could view the real-time status for each customer and easily create a sortable list of all their financial information. This included daily, monthly, and yearly revenue as well as profitability or volume for each seller, customer, or supplier, together with dozens of other statistics on a specially designed page.

Adoption is important! We treat adoption with maximum attention. The details that are familiar are digitized so users will have a gentle learning curve.

The digital process closely mirrors the existing one. We updated the procedures only to simplify tasks, reduce redundancy, and automate outputs. Special attention was given to familiar details.

As an example: we even took the good old “Post-It” notes that they were used to and created an improved, virtual replica. Now it’s available in every section where custom information is required, both public and private.

The outcome: digital transformations brings back control

The digital transformation of the Medfreight’s business allowed them to take back control in a turbulent market, making life easier for management while simplifying tasks for their sales, support and operations teams.

Final Result: Less time wasted on operations, leaving more time for other tasks and cutting costs.